Background:

Studies have shown that the 253.7nm ultraviolet light of ozone has a large absorption coefficient, and the ultraviolet light at this wavelength is attenuated by ozone, which conforms to the Lambert-Beer law. The ozone gas analyzer adopts the principle of ultraviolet absorption. It uses a stable ultraviolet light source to generate ultraviolet light. The lightwave filter filters out other wavelengths of ultraviolet light. Only 253.7nm ultraviolet light is allowed to pass. After passing through the sample photoelectric sensor, it is absorbed by ozone to reach the sampling photoelectric For the sensor, the electrical signals of the sample photoelectric sensor and the sample photoelectric sensor are compared, and the mathematical model is calculated according to the Lambert-Beer law to obtain the ozone concentration.

The semiconductor ozone sensor uses gas-sensitive semiconductor materials, such as WO3, Sn0, In203, and other pieces of oxide to make sensitive elements, when they absorb ozone, oxidation-reduction reactions occur, generate or release heat, so that the temperature of the element changes accordingly. The resistance changes, the ozone concentration is converted into an electrical signal, and the ozone concentration is measured. Generally, as the lifted concentration increases, the resistance value of the component increases significantly, and within a certain range, a linear relationship is present.

The electrochemical ozone sensor is composed of a working electrode, counter electrode, participating electrode, electrolyte, and circuit system. A constant potential value can be maintained between the working electrode and the participating electrodes. When ozone diffuses into the sensor, a reduction reaction occurs at the working electrode, an oxidation reaction occurs on the electrode, and a small current is formed between the electricity price and the working electrode, and this current enters The ozone concentration of the sensor is proportional to a certain range, and finally processed by the circuit system to calculate the ozone content.

How to choose ozone sensor?

When purchasing an ozone detector, you must first clarify the characteristics of the use environment and the purpose of use and combine the stability, sensitivity, selectivity, and corrosion resistance of the ozone monitoring equipment to choose.

Stability refers to the stability of the basic response of the sensor during the entire working time, which depends on the zero drift and interval drift. Zero drift refers to the change in sensor output response during the entire working time when there is no ozone. Interval drift refers to the output response change of the sensor continuously placed in ozone, which is manifested as the decrease of the sensor output signal during the working time. Ideally, a sensor under continuous working conditions, the annual zero drift is less than 10%.

Sensitivity refers to the ratio of the sensor output change to the measured input change, and it mainly depends on the technology used in the sensor structure. The design principles of most gas sensors use biochemistry, electrochemistry, physics, and optics. The first thing to consider is to select a sensitive technology that has sufficient sensitivity for the detection of the target gas’s valve limit (TLV-threshold limit value) or the lowest explosive limit (LEL-lower explosive limit) percentage.

Selectivity is also called cross-sensitivity. It can be determined by measuring the sensor response produced by a certain concentration of interfering gas. This response is equivalent to the sensor response produced by a certain concentration of ozone. This characteristic is very important in the application of tracking multiple gases because the cross-sensitivity will reduce the repeatability and reliability of the measurement. The ideal sensor should have high sensitivity and high selectivity.

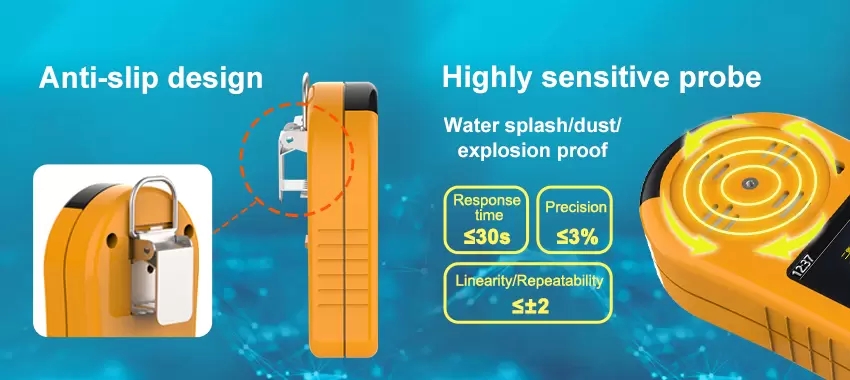

Corrosion resistance refers to the ability of the sensor to be exposed to a high volume fraction of target gas. When a large number of gas leaks, the probe should be able to withstand 10-20 times the expected gas volume fraction. Under normal working conditions, the sensor drift and zero-point correction value should be as small as possible.

Explosion-proof O3 Gas Sensor

Fixed Ozone Gas Alarm Detector can be used in oil refineries, chemical plants, liquefied petroleum gas stations, boiler rooms, painting plants and other places where gas exists. Gas concentration monitoring can be performed quickly and accurately. Factory direct sales, quality guaranteed.More gas monitoring equipment welcome to consult JXCT.