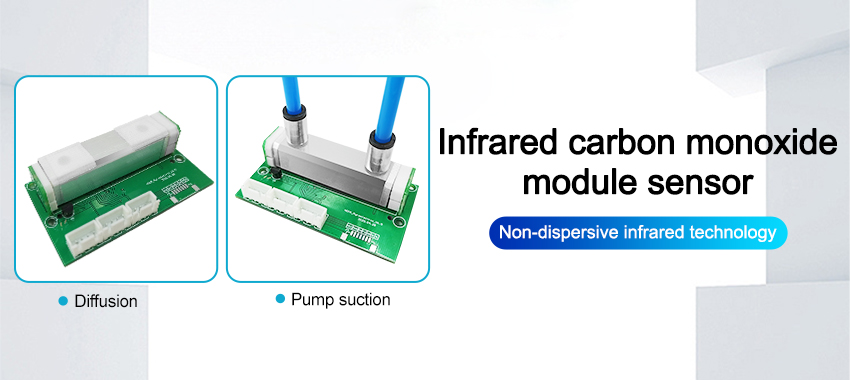

Product Introduction:

NDIR CO Sensor Module,After the infrared radiation emitted by the infrared light source is absorbed by a certain concentration of the gas to be measured, the spectral intensity proportional to the concentration of the gas will change. Therefore, the concentration of the gas to be measured can be inversely calculated by calculating the variation of the spectral light intensity. Infrared CO sensor module is based on NDIR infrared absorption detection principle, combining advanced optical path, precision circuit and intelligent software to form a general infrared CO sensor module. This product adopts imported MEMS infrared light source and dual channel pyroelectric detector, measurement and reference signal processing, and temperature compensation, even in harsh temperature and environmental conditions, also can obtain stable and reliable measurement results.

* Models:JX-CO-103

* Minimum order quantity: 1 piece

* Delivery time: within 24 hours

Parameters:

Response time: < 30s (25°C)

Preheating time: < 1min (25°C)

Accuracy achieved: < 3min (25°C)

Working voltage: 9-24V DC

Average power consumption: <60mA

Working humidity: 0~95%RH (non-condensing)

Working temperature: -10~75°C, the maximum temperature resistance is 85°C; temperature compensation range: -10~60°C (factory default)

Storage temperature: -20~70℃

Infrared light source band: 2 -14 μm

Features:

1. Imported MEMS infrared light source and dual-channel pyroelectric detector are used to process the measurement and reference signals and perform temperature compensation.

2. Even under harsh temperature and environmental conditions, stable and reliable measurement results can be obtained

3. Good selectivity unique to NDIR products,

4. High sensitivity, no oxygen dependence, long life

Attention:

Precautions for use

(1) During the welding, installation and use of the sensor, the cavity should be prevented from being subjected to any direction of pressure.

(2) If the sensor needs to be placed in a narrow space, avoid contact with other charged devices to prevent static electricity from damaging the infrared detector.

(3) The sensor should be kept away from heat sources and other heat radiation.

(4) The sensor should be calibrated regularly, and the calibration cycle is recommended not to exceed 12 months.

(5) The gas to be measured passing into the cavity must pass through the dust filter.

(6) In order to ensure the normal operation of the sensor, the power supply voltage must be kept in the range of 9V-24V DC, and the power supply current must not be lower than 150mA. If it is not within this range, the sensor may fail, the sensor output concentration is low or the sensor cannot work normally .

FAQs:

1.DA output (analog voltage signal)

The voltage output range and corresponding range can be customized according to customer needs

Example: 0.4 – 2V corresponds to an output of 0 – 20W ppm

0 – 3.3V corresponding output 0 – 50W ppm

Voltage signal output range: 0-5V

2. Scope of application

It can be widely used in coal mine gas detection, oil and gas detection, chemical gas production and air detection process monitoring, and can be installed in chemical industry, coal mine, oil field, intelligent building, sound and light alarm controller, robot, automobile and other applications.

Reviews

There are no reviews yet.