Product Introduction :

JXCT analog wind speed sensor, features small and light, easy to carry and assembly, three cups of design concept can be effective for the external environment information, shell is made of high quality aluminum alloy profiles, outside the plating pensu processing, has a good anticorrosive and prevent erosion, etc, can guarantee the instrument use for a long time no rust cut phenomenon, at the same time, cooperate with internal smooth bearing system, The accuracy of information collection is ensured. It is widely used for wind speed measurement in greenhouse, environmental protection, weather station, ship, dock, aquaculture and other environment.

* Models:JXBS-3001-FS

* Minimum order quantity: 1 piece

* Delivery time: within 24 hours

Features:

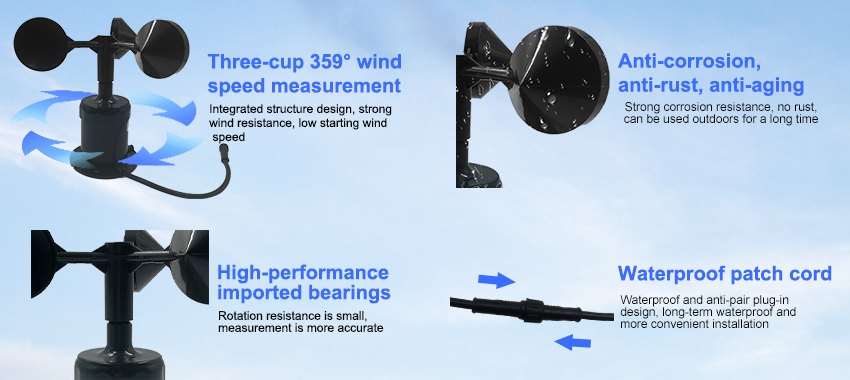

1. Internal anti-electromagnetic interference treatment.

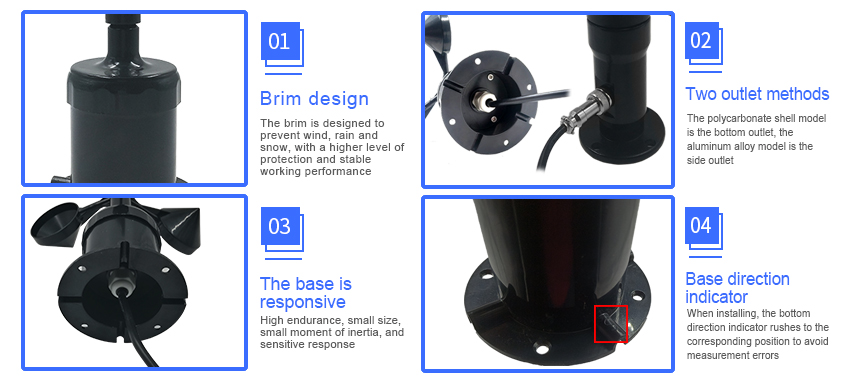

2. The bottom outlet method is adopted to eliminate the aging problem of aviation plug rubber pads, and it is still waterproof after long-term use. Free cloud platform.

3. Using high-performance imported bearings, low rotation resistance, accurate measurement.

4. Polycarbonate shell, high mechanical strength, high hardness, corrosion resistance, no rust, and long-term use outdoors.

5. The structure and weight of the equipment are carefully designed and distributed, with a small moment of inertia and sensitive response.

6. Multiple output modes are optional: 0-5V, 0-10V, 4-20mA

Parameters:

Measurement parameter: wind speed

Wind speed measurement range: 0-30m/s

Wind speed measurement accuracy: ±1m/s

Response time: less than 5 seconds

Communication port: 0-10V

Power supply: 12V to 24V DC

Power consumption: < 1 w

Operating temperature: -30-80℃

Attention:

Installation instructions

Mounted with flange, threaded flange connection that the lower part of the wind sensor fitting firmly fixed in the flange plate, chassis on the circumference of the four Φ 6 mm mounting holes, using bolts should be firmly fixed to the bracket, to keep a complete set of equipment at the best level, ensure the accuracy of the wind data, flange connection is convenient to use, can withstand greater pressure.

FAQs:

1. Inflexible rotation and jamming

When the new wind speed sensor appears in this situation, it may be due to the loose internal parts leading to bearing rotation problems. Measure the wind speed sensor after powering the device. If the sensor is faulty, contact the manufacturer to replace it. Manually rotate the wind cup at the top of the wind speed sensor. If the cup does not rotate smoothly, it indicates that there is a problem with the device connection. You can handle it under the guidance of technical personnel.

If the old wind speed sensor is not sensitive during the working process, the surface of the sensor needs to be cleaned first to see if there are obstacles around the wind cup that hinder its rotation. Such as shelter from leaves, the icing on the wind cup, tilt of the sensor, etc. Even a small feather stuck on the wind cup will cause a big deviation in the value.

Secondly, if the above problems are excluded, you need to manually remove the sensor and clean the dirt and other stolen goods inside. In windy weather, some fine gravel may enter the sensor shaft and affect its operation. Therefore, users should maintain and clean the wind speed sensor in time to ensure the service life of the equipment. Finally, the use time of wind speed sensor is too long, the internal components are easy to aging or fall off. At this time, it is necessary to replace the accessories of the wind speed sensor or purchase a new sensor directly.

2. The wind speed is zero

There are three possible reasons the wind speed sensor reading is zero: First, the reed switch used as the sensor in the device begins to malfunction. A gentle tap on the anemometer body above the wind shaft will sometimes restore proper operation. If possible, tend to identify reed pipe problems, but sooner or later need to be resolved. Contact technical personnel for replacement.

Second, another possible cause of intermittent speed readings is that the cable is damaged and the speed conductor is in intermittent contact. Check the cable and power supply system for problems, connect the standby equipment, and turn the wind shaft. If the rotating shaft rotates flexibly and there is no obvious noise, it indicates that the rotating part of the wind speed sensor works normally. Check the reading for data. If data is available, check whether other components work properly. If no data is available, the wind speed sensor is faulty and needs to be replaced.

Finally, if the starting wind speed is too high, this cause is less likely. If you are measuring at a location and the current wind speed is too low, the reading will always be zero, even if you cannot reach the starting wind speed of the wind speed sensor. Therefore, to avoid this situation, users should take measurements in multiple locations and at multiple points in time. Measure whether to display readings under different wind conditions.

3. The anemometer has obvious deviation from other anemometers

It is not common for users to think their anemometer reading is inadequate. Several practical anemometer problems can cause low speed readings. The most obvious is a rigid bearing on the shaft of the wind cup, which can be remedied according to the above reasons, or a failure of the reed tube, which may result in a connection to another anemometer. There is a deviation in the reading.

The measured speed of wind speed varies with height. Therefore, the two wind speed sensors installed should be at the same height and at the same exposure. There is also a less obvious reason. Wind speeds are erratic, especially inland, but are usually short high and short low during gusts.

Most of the wind speed sensor manufacturers on the market have different equipment measurement principles, and the range of wind speed measured by different equipment is also very different, so the measured value between different equipment is not comparable.

4. Indirect reading of the wind speed sensor

If the wind speed sensor with Modbus output is faulty, you need to rectify the circuit fault. The fault of the 4-20 MA wind speed sensor may be caused by unstable connection of the terminal device or faulty connection cables. The reason for the failure of the network wind speed sensor is that the current network environment is unstable, the signal transmission is interrupted, and the signal is unstable.

Reviews

There are no reviews yet.