Soil NPK sensors are devices measure the levels of nitrogen (N), phosphorus (P), and potassium (K) in the soil. These sensors can provide real-time data on the nutrient content of the soil, helping farmers optimize their fertilizer application and improve crop yield.

Working Principle of NPK Sensors

NPK sensors work base on various technologies, but one common approach is using ion-selective electrodes. These electrodes are designed to selectively detect the ions of interest (N, P, and K). When these electrodes come into contact with the soil, they generate electrical signals proportional to the concentration of the specific ion present.

soil NPK sensor actually measures the electrical conductivity of the soil. The manufacturer multiplies the measured conductivity value by a corresponding factor (based on the conventional soil content of nitrogen, phosphorus and potassium) to arrive at a value for the nitrogen, phosphorus and potassium content.

Due to the different soils and environments on site, such sensors cannot accurately measure the actual nitrogen, phosphorus and potassium content of the soil on site, but give an empirical, theoretical value.

Reagents in NPK Sensors

Most modern NPK sensors do not require the use of reagents. Instead, they rely on advanced electrochemical techniques or spectroscopy to directly measure the ions in the soil. These methods eliminate the need for reagents, making the measurement process more efficient and cost-effective.

Measurement Ranges and Individual Parameters

The measurement ranges of Soil NPK sensors can vary depending on the specific model and technology used. However, typical ranges for each parameter are as follows:

1. Nitrogen (N): The measurement range for nitrogen levels in the soil can be anywhere from 0 to 200 kg/ha. This range allows farmers to assess the adequacy of nitrogen fertilization and make necessary adjustments to optimize crop growth.

2. Phosphorus (P): The measurement range for phosphorus in the soil typically falls between 0 and 100 mg/kg or ppm. Monitoring phosphorus levels helps farmers determine if additional fertilization is required to meet crop demands and prevent deficiencies.

3. Potassium (K): The measurement range for potassium in the soil is usually from 0 to 400 mg/kg or ppm. Monitoring potassium levels is crucial for maintaining plant health, as potassium is involved in various physiological processes.

Each parameter can be measured individually by the NPK sensor. By selectively applying different measurement techniques or electrodes specific to each ion, the sensor can determine the concentration of nitrogen, phosphorus, and potassium separately.

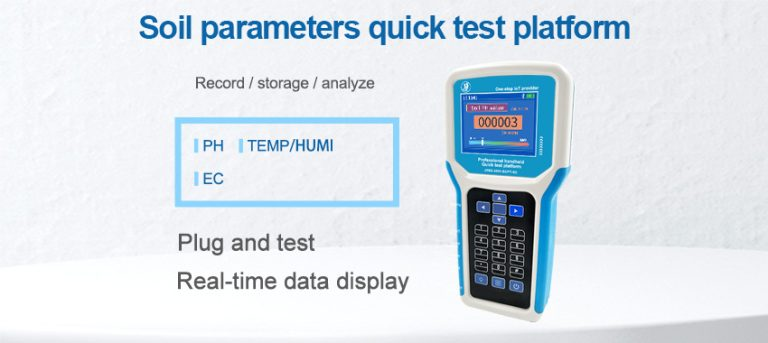

How to use Portable NPK soil tester:

1. Quick test method

To measure the position, avoid rocks and ensure that the steel needle does not touch hard objects. Discard the top soil at the required measurement depth, keeping the original tightness of the soil below, and insert the sensor vertically into the soil. Don’t rock from side to side. It is recommended to measure the average multiple times in a small area of a measurement point.

2, buried measurement method

Dig a pit with a diameter >20cm vertically, insert the induction needle horizontally into the pit wall to a predetermined depth, and fill the pit tightly. After a period of stabilization, measurements and recordings can be made for days, months, or even longer.

Conclusion:

NPK sensors are valuable tools for agriculture, allowing farmers to monitor nitrogen, phosphorus, and potassium levels in the soil accurately. These sensors typically employ ion-selective electrodes to measure the ions of interest. Modern NPK sensors eliminate the need for reagents, utilizing advanced electrochemical or spectroscopic techniques. The measurement ranges for nitrogen, phosphorus, and potassium vary, with each parameter capable of being measured individually by the sensor. Understanding the working principles and parameters of NPK sensors empowers farmers to make informed decisions regarding fertilizer application and optimize crop growth and health.