The Soil NPK sensor is suitable for detecting the content of nitrogen, phosphorus, and potassium in the soil, and judging the fertility of the soil by detecting the content of N, P, and K in the soil. The stainless steel probe of the soil npk sensor can be buried in the soil for a long time and is resistant to long-term electrolysis, salt, and alkali corrosion. The shell is vacuum potted and completely waterproof.

The working principle of a Soil NPK sensor involves the use of electrodes that are into the soil. These electrodes measure the electrical conductivity of the soil, which is influenced by the presence of ions such as nitrate (NO3-), phosphate (PO4-3), and potassium (K+). The sensor then converts the electrical conductivity readings into NPK concentrations using calibration equations.

There are several parameters that are important in the functioning of a NPK sensor:

- Electrical conductivity: This is the primary parameter measure by the sensor. It is influence by the concentration of ions in the soil, including NPK, as well as other factors such as moisture content and soil texture.

- Calibration equations: These are mathematical relationships that are convert the electrical conductivity readings into NPK concentrations. Calibration is essential to ensure the accuracy of the sensor readings, and it requires regular updates to account for changes in soil properties over time.

- Soil moisture: The moisture content of the soil can affect the electrical conductivity readings, so it is important to take this parameter into account when interpreting the sensor data. Some sensors may have built-in moisture sensors to compensate for this effect.

- Soil temperature: Like moisture, soil temperature can also influence the electrical conductivity of the soil. Some sensors may have temperature compensation features to account for this effect.

- Sensor placement: The placement of the electrodes in the soil is crucial for accurate readings. The sensors insert to a consistent depth and location to ensure uniform measurements across the field.

Soil NPK sensors have several advantages over traditional soil testing methods. They provide real-time, on-site measurements, allowing for more timely and targeted nutrient management decisions. They also enable the monitoring of nutrient dynamics in the soil, which can help optimize fertilizer application and minimize nutrient losses to the environment.

Soil npk sensor parameters

Power supply: 5-30VDC

Maximum power consumption: ≤0.15W

Operating temperature: -40~80℃

NPK parameters:

Range: 0-1999 mg/kg(mg/L)

Resolution: 1 mg/kg(mg/L)

Precision: ±2%FS

Response time: ≤1S

Protection grade: IP68

Probe material: 316 stainless steel

Sealing material: Black flame-retardant epoxy resin

Default cable length: 2 meters

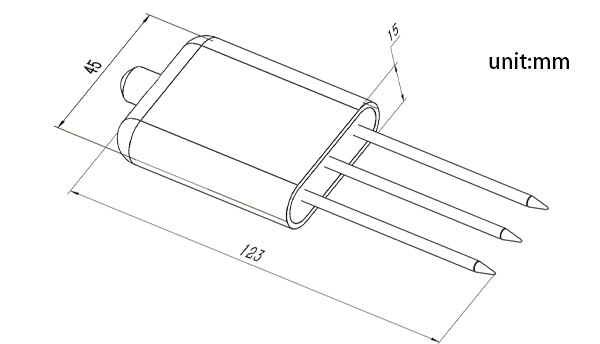

Dimensions: 45*15*123mm

Output signal: RS485/4-20ma/0-5v/0-10v

How to use soil npk sensors

1.Quick Test Method

measurement location, avoid rocks, ensure that the steel needle does not touch hard objects, throw away the surface soil according to the required measurement depth, maintain the original tightness of the soil below, hold the sensor vertically and insert it into the soil. Do not shake left and right. It is recommend to measure multiple times for average value within a small range of a measuring point.

2. Buried measurement method

Dig a pit with a diameter> 20cm vertically, insert the sensor needle horizontally into the pit wall at a predetermined depth, and fill the pit tightly. After a period of stability, measurement and recording carrie out for several days, months, or even longer.