Inline Water Quality Sensor

Inline water quality sensor allow for continuous monitoring of water quality parameters at various points throughout the water treatment process. This could be for the detection of contaminants, pH levels, temperature, turbidity, and other critical parameters that affect the quality of water.

In this article, we discuss how inline water quality sensors help improve water treatment processes while increasing operational efficiency and reducing risks.

How Inline Water Quality Sensors Work

Inline water quality sensors continuously measure the concentration or level of specific parameters without interrupting the flow of water. These sensors detect the smallest changes in water quality parameters over time, allowing operators to make real-time adjustments. They are installed directly into the water stream in a fixed position and connected to a data acquisition system that collects and analyzes the readings.

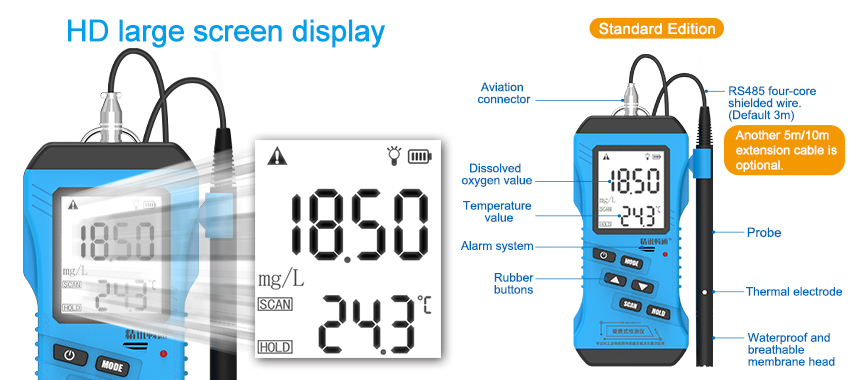

There are several types of inline water quality sensors available, including those that use optical, electrochemical, and thermal measurement techniques. Optical sensors use light to detect changes in water quality, while electrochemical sensors use electrodes to sense electrical changes in the water. Thermal sensors measure changes in temperature and conductivity in the water.

The sensor’s output signals are typically sent to a programmable logic controller (PLC), which converts the data into a meaningful format that is easily interpreted by plant operators. These operators can then make data-driven decisions to optimize and control the water treatment process.

Benefits of Using Inline Water Quality Sensors in Water Treatment Processes

Improved Water Quality

Inline water quality sensors enable water treatment plants to continuously monitor the water quality parameters in real-time, providing a more accurate representation of the water quality than traditional grab sampling methods. With real-time data, plant operators can quickly detect changes in water quality before the water is released into distribution systems.

Increased Operational Efficiency

The use of inline water quality sensors helps operators to optimize and control the water treatment process efficiently. They can identify any inefficiencies or bottlenecks in the process and make necessary adjustments to ensure optimal performance. This speed up the response time to problems, reducing downtime, and increasing productivity.

Cost-Effective

Inline water quality sensors are cost-effective compared to traditional water quality monitoring techniques that require manual sampling processes. The sensors enable continuous and real-time monitoring of water quality parameters, reducing the need for labor-intensive grab sampling. Therefore, it reduces overall operational costs by reducing maintenance and equipment wear and tear.

Reduced Risk of Contamination

Inline water quality sensors also help reduce the risk of contamination. As the sensors perform automatic and continuous monitoring of water quality parameters, they provide an early warning about changes in water quality, minimizing the exposure of water to contaminants like disease-causing microorganisms.

Applications of Inline Water Quality Sensors

A. Industrial Water Treatment

Water quality is essential in many industrial applications, where poor water quality could lead to production strain or worse yet, rights violations or liabilities. For example, the microelectronics industry that requires a high purity water supply needs to constantly monitor their water treatment processes to prevent impurities. The pharmaceuticals industry also needs clean water supply free from chemicals and toxins to maintain suitable manufacturing standards. The installation of inline water quality sensors enable industries to optimize water quality, minimizing operational losses, as well as improve their final product quality.

B. Municipal Water Treatment

Inline water quality sensors are critical for municipal water treatment purposes, where large quantities of people depend on potable water supply. For instance, many municipalities require the ability to continuously monitor water quality during any stage of their treatment process, from the point of abstraction through distribution and into their customers’ homes or businesses. The installation of inline water quality sensors in their treatment plants provides a reliable mechanism for ensuring adequate supply and high-quality water.

C. Aquaculture

Inline water quality sensors also play a significant role in the aquaculture industry where maintaining good water quality is essential for fish health and growth. Farmers install these sensors in their aquaculture ponds, continuously monitoring the water quality parameters, including dissolved oxygen level, pH, ammonia, temperature, among others. The data collected enables farmers to optimize their feeding rates, reduce metabolic wastage, and keep fish healthy.

D. Recreational Water Management

Inline water quality sensors can be installed in swimming pools and spas to continuously monitor the water quality parameters. These sensors ensure that the proper amounts of sanitizer and other chemicals are maintained at safe levels. It’s important to remember that exposure to improperly treated water can lead to various illnesses such as Legionnaire’s disease, Cryptosporidiosis, and other waterborne infections.

Conclusion

Inline water quality sensors are vital instruments used to improve water quality and safety and increase operational efficiency in water treatment processes. Continuous monitoring of water quality parameters provides real-time data, which enables operators to make informed decisions that optimize and control the water treatment process and prevent system failure. The sensors are a cost-effective solution to traditional water quality monitoring techniques and provide a more accurate representation of water quality changes. Overall, Inline water quality sensors help to maintain high-quality water standards while reducing operational costs and risks.