What are mems gas sensor ?

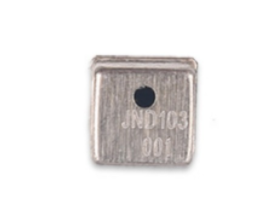

MEMS gas sensor are micro-sized devices that can detect and measure various gases in the air. These sensors use microfabrication techniques to create tiny structures that can sense changes in the surrounding environment. MEMS gas sensors have a wide range of applications, from monitoring air quality in buildings to detecting toxic gases in industrial settings.

Mems gas sensors work on the principle

MEMS gas sensors work on the principle of gas adsorption, which means that gases adhere to the surface of the sensor. When a gas molecule comes into contact with the sensor surface, it causes a change in the electrical properties of the sensor. This change can be measured and used to determine the concentration of the gas in the surrounding air.

The advantage of MEMS gas sensors

Advantage one, Small size.

Because they are so small, they can be integrated into a wide variety of devices, including smartphones, wearables and Internet of Things sensors. This makes MEMS gas sensors ideal for applications where space is limited and traditional gas sensing technology is impractical.

Advantage two, low power consumption

Because they use tiny structures and low-power electronics, they consume very little energy compared to traditional gas sensors. This makes them ideal for battery-powered applications, where power consumption is a key factor.

Advantage three, sensitivity and selectivity

They can even detect trace amounts of gas in the air, making them ideal for applications with high sensitivity requirements. In addition, because they are highly selective, they can distinguish between different types of gases, which is important for applications where specific gases need to be detected.

The application of MEMS gas sensor

MEMS gas sensors is in air quality monitoring.

With the rise of urbanization and industrialization, air pollution has become a significant health concern. MEMS gas sensors can be used to monitor air quality in buildings and outdoor environments, allowing for early detection of harmful pollutants. This can help to improve public health by reducing exposure to harmful pollutants.

MEMS gas sensors are detect and monitor toxic gases.

In industries such as oil and gas, mining, and chemical manufacturing, workers may be exposed to hazardous gases such as carbon monoxide, hydrogen sulfide, and methane. MEMS gas sensors can be used to monitor these gases in real-time, alerting workers to potential hazards and helping to prevent accidents.

MEMS gas sensors are used in vehicle emission controllers.

Modern cars are equipped with a variety of sensors to monitor engine performance and emissions. MEMS gas sensors can be used to measure exhaust gas concentrations, allowing for real-time monitoring of emissions. This is important for ensuring compliance with emissions regulations and for reducing air pollution.

MEMS gas sensors have potential applications in the medical field.

They can detect and monitor gases in breath analysis, which can be used for disease diagnosis and monitoring. For example, MEMS gas sensors could be detect gases in the breath of patients with lung cancer, allowing for early detection and treatment.

In conclusion, MEMS gas sensors are micro-sized devices that can detect and measure various gases in the air. They have several advantages over traditional gas sensing technologies, including small size, low power consumption, high sensitivity, and selectivity.

MEMS gas sensors have a wide range of applications. As technology continues to advance, MEMS gas sensors are likely to become even more important in a variety of industries and applications.