Industrial harmful gas detectors monitor the presence of gases in a specified area and sound an alarm when they reach dangerous levels. Gas detectors are typically installed where there is a potential for a gas leak, and where unsafe gas levels pose an immediate danger to workers or equipment.

Harmful gas detectors are widely used by industries including gas and oil, medical, mining, nuclear, construction, food and beverage, and industrial.

What is harmful gas detectors?

Harmful gas detectors help prevent issues by monitoring potential leakage areas for harmful gas levels. They are commonly used on oil rigs and in chemical plants and manufacturing facilities where toxic fluids and gases are being stored and processed.

How Do harmful Gas Detectors Work?

Harmful gas detectors and oxygen gas detectors work by measuring the concentration of a specific gas in the air. RC Systems specializes in fixed gas detection with either remote or locally mounted sensors. One or more types of gas detectors might be used in the same area, depending on the different gases involved and the size of the work area.

Gas detectors are programmed with pre-set levels that vary depending on the type and concentration of gas being monitored. A sensor inside the toxic gas detector reads the gas levels, and when they rise above or fall below the specified level, an alarm activates. Sensors are made from electrochemical cells, and the alarm can be visual or audible. Readings can be sent via a digital signal or analog signal to a control room, and alarms can actuate local relays for the operation of alarm safety devices such as horns, fans, valves, etc.

Selecting the Right Type of Gas Detector for Your Application

Important things to consider when selecting a harmful gas detector include:

- Reliability: This is perhaps the most crucial because oxygen detectors that frequently malfunction or have a short product life can put your workplace at danger.

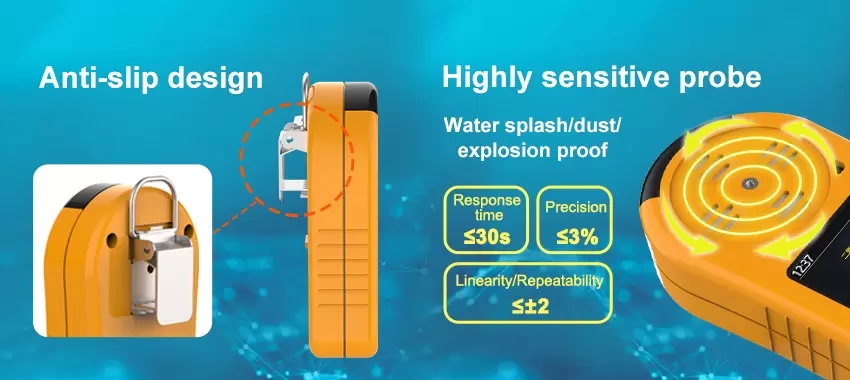

- Features & Usability: You want to select an oxygen gas detector that is durable, easy to install, and can withstand the conditions of your operating environment. The device should also fit your data recording requirements and be easy to maintain and calibrate.

- Reading Sensitivity & Accuracy: Some gas detection applications require a higher level of sensitivity than others, so make sure your toxic gas detector can register readings within your required range.

- Alarm Response Time: When it comes to oxygen or toxic gas reaching dangerous levels, every second counts. Make sure the gas detector you select has a response time that allows you enough time to react and remedy the issue.

- Sensitivity to Environmental Factors: Depending on the operating environment, a gas detector might be exposed to heat, moisture, humidity, or other gases. It is critical that these factors do not affect the reliability of the readings and results provided by your toxic gas detector.