Product Introduction:

Product Introduction:

Fixed NH3 transmitter adopts professional ammonia concentration sensor probe as the core detection device, which has the characteristics of wide measuring range, high precision, good linearity, good generality, convenient use, easy installation, long transmission distance and moderate price.

* Models:JXBS-4001-NH3

* Minimum order quantity: 1 piece

* Delivery time: within 24 hours

Features:

1. Using remote infrared remote control technology, parameters can be modified without disassembly.

2, support a variety of gas detection, range can be customized.

3, analog, RS485 and other output mode to choose from.

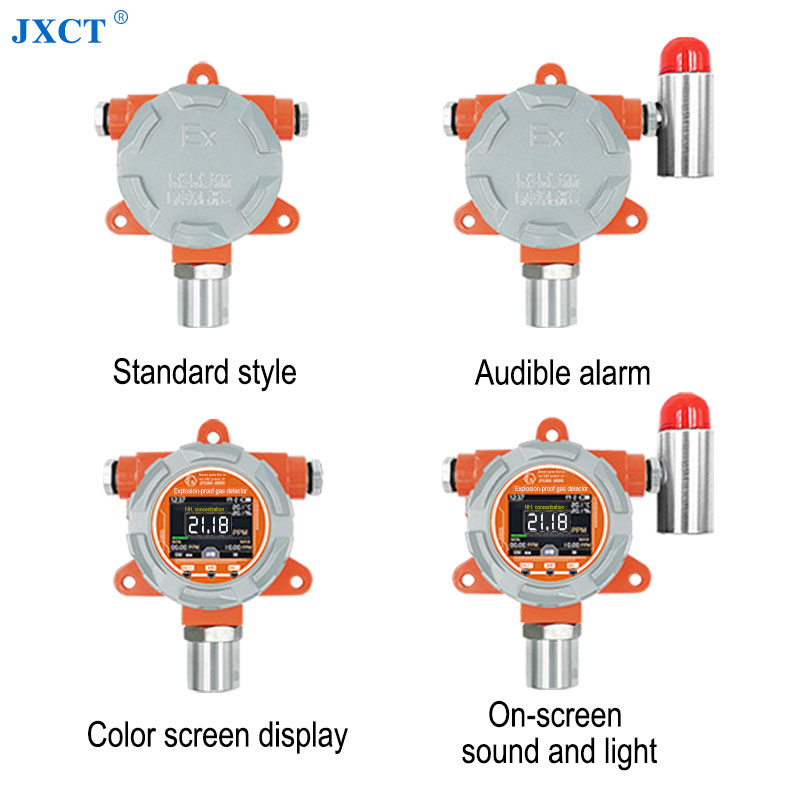

4, Optional high-quality LCD, on-site directly view the value.

5, 10~30V wide voltage DC power supply, can adapt to various on-site DC power supply.

6, gas detector adopts wall-mounted waterproof shell, easy installation.

Parameters:

Measurement accuracy:3%F.s

Response time;<60s

Measurement method:Electrochemical probe

Interface form:Analog quantity/RS485

Power supply:12-24V DC

Power consumption:<1W

Operating temperature:-20°C-50°C

Working environment humidity:15-90%RH (non-condensing)

Explosion-proofgrade:ExdlI CT6

Attention:

Where should a stationary gas detector be installed?

For detecting gases lighter than air (such as methane and ammonia), a fixed gas detector should be installed at a higher position and a cone collector should be used.

When detecting gases heavier than air (such as butane, sulfur dioxide, etc.), the detector should be installed at a low position.

Consider the possible behavior of escaping gas under the action of natural flow and pressurized flow. Install the detector in the ventilation duct where appropriate.

Possible damage from natural events, such as rain or flooding, needs to be taken into account when locating the probe. For detectors installed outside, use weatherproof devices.

If installed in a hot climate and direct sunlight, use a detector visor.

When considering process conditions. For example, butane and ammonia are usually heavier than air, but if released from high-temperature and/or pressurized production lines, these gases rise instead of falling.

The detector should be positioned slightly away from the high pressure assembly to allow the formation of aerosols. Otherwise, the leaking gas may pass through the detector at high speed without being detected.

Consider the convenience of functional testing and maintenance.

The detector shall be mounted in position with the detector face down. This effectively prevents dust or moisture from gathering in front of the detector, allowing gas to enter the detector smoothly.

When installing an open-circuit infrared device, ensure that the infrared beam is not permanently shielded or blocked. Short-term obstructions by vehicles, field workers, birds, etc., can be allowed.

Ensure that open circuit equipment is installed on a stable and vibration-free structure.

FAQs:

1. How to define the effective detection range of the stationary gas detector?

The effective covering plane radius of the combustible gas detector should be 7.5m indoors and 15m outdoors. Detectors can be set within the effective coverage area. The distance between the toxic gas detector and the release source should not be greater than 2m outdoors and 1m indoors.

2. How to maintain the fixed gas detector?

Wipe the surface clean periodically with a soft, damp cloth.

3. Where can I use a stationary gas detector?

Fixed gas detector can measure a wide range of gases, can be used for petrochemical, coal, metallurgy, chemical, municipal gas, environmental monitoring and other places of on-site detection. Can meet the special occasion measurement needs. It can detect gas concentration or leak in tunnels, pipelines, storage tanks, and confined Spaces.

4. What are the types of gas detectors?

Gas sensor according to the principle can be divided into infrared gas detector, thermal magnetic gas detector, electrochemical gas detector, semiconductor gas detector, ultraviolet gas detector, etc.

Reviews

There are no reviews yet.